Skip to content

What is GPSC Nacen solfware Why do we use it?

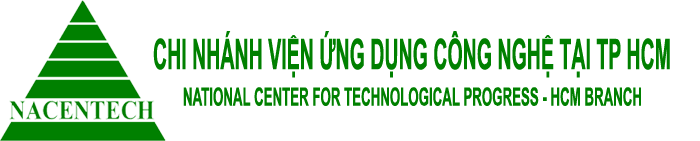

- The It software is to analysis and pre-determined times solution across the sewn industry.

- There is only one industry standard to benchmark time and costs in factories. And there is only one solution that allows you to optimize time and cost from the moment the lines start running. There is only one common language for time, cost, capacity and compliance, spoken between brands and their vendor partners.

- In the sewn-products industry, some 80% of the cost is committed at the design sampling stage. It gives your facility a costing tool that allows you to accurately predict the best-known methods of manufacturing prior to production. The system provides for the management of all operation standards and the basis of rapid labor cost estimating.

- GPSC Nacen creates a “discipline” for your facility – a common standard language for engineering, pre-costing, and productivity applicable to every phase of your operation.

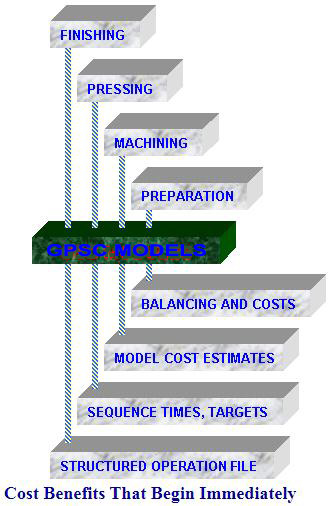

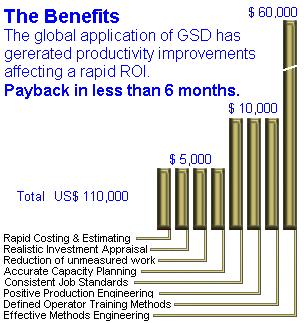

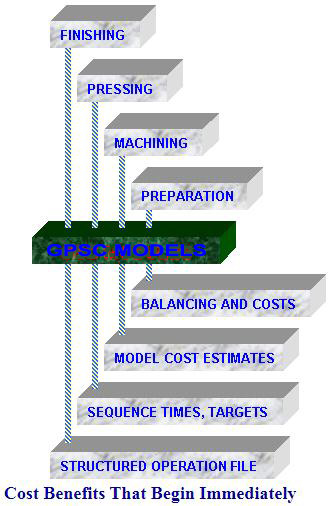

Cost Benefits That Begin Immediately

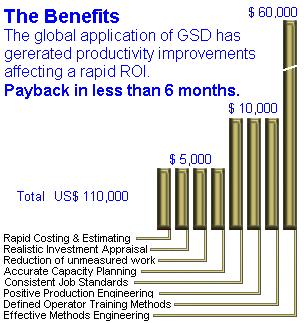

- For clients, It has delivered immediate productivity improvement and cost savings. Our results show: Productivity improvement averaging a substantial, measurable of the direct labor payroll.

- Return of investment: six to eight months, based on a 100-operator plant Enhanced engineering productivity with same or reduced staffing Improved pre costing through GPSC Nacen’s unique “skeleton” costing process.

Simplicity and Accuracy with NACEN GPSC

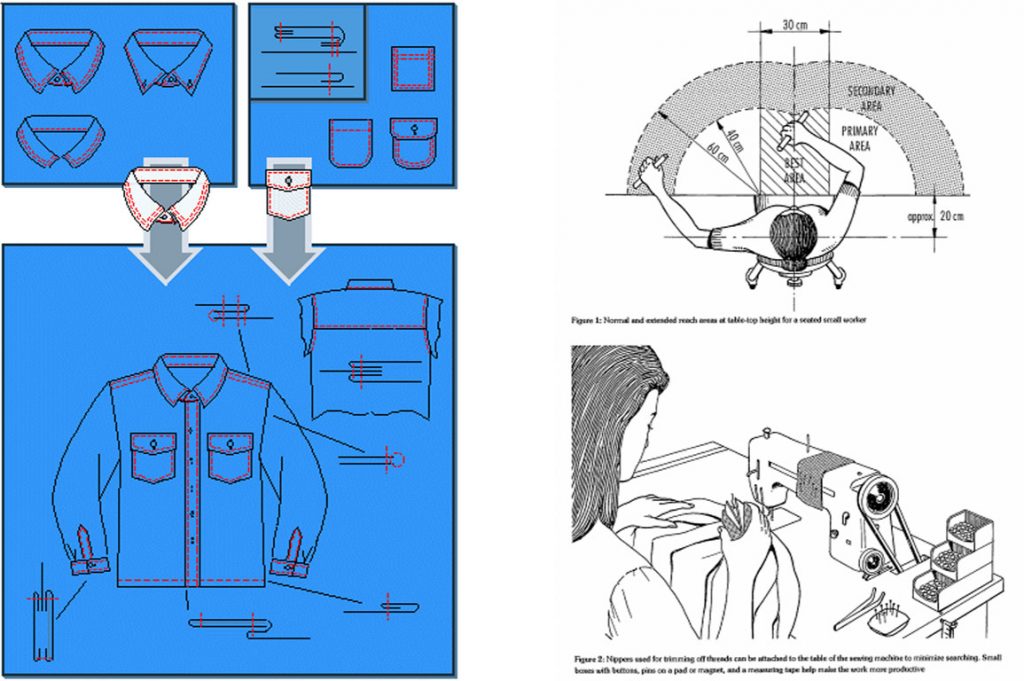

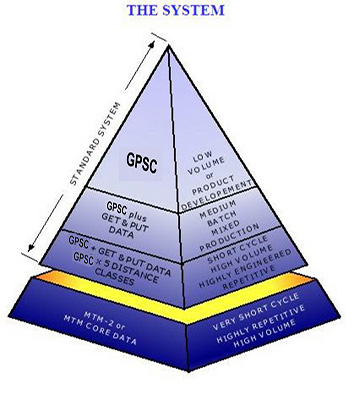

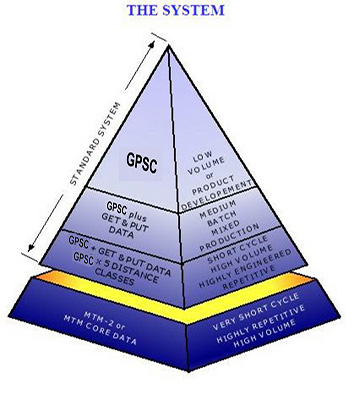

- NACEN GPSC is a computerized standard data system developed specifically for the sewn-products industry. The statistically validated elemental codes, constructed from a unique MTM™ (Methods Time Measurement) CORE DATA, represents a simple, universal language which is easy to learn and communicate.

- The same simple codes can be fine-tuned to meet with any level of engineered methods, thus ensuring fast, consistent application with MTM-level accuracy. This is true whether the system is used in high-fashion or large volume/repetitive manufacturing environments.

NACEN GPSC: Ultimate Costing System

- Efficient methods, accurate labor standards and preseason style costing are fundamental to the success of a sewn-products facility.

- NACEN GPSC provides fast, accurate rates in a fraction of the time compared with other systems. NACEN GPSC allows pre-costing of various stages of manufacturing. The system provides reliable, measurable information on:

- Optimum Standard Allowed Minute values

- Production-run efficiency (overall & component)

- Costing per style

- Performance related indices

Besides:

- Substantial time reduction for style costing and style introduction.

- Improvement in overall consistency rates.

- Evaluation and justification of new equipment methods.

- Elimination of lost business caused by overpricing of jobs.

- Overall management of manufacturing standards data base.

- Efficiency of operator training via method specification.

- Rapid quantification of changes in design, materials, volume, technique and quality.

- Reduction of off-standard/average payments.

- Setting and pre-engineering of consistent and accurate rates.

- Elimination of lost income caused by underpricing of jobs.

- Data transfer capabilities to other systems.

- Reduction of clerical time.

Further Benefits of NACEN GPSC:

- Customization – NACEN GPSC is designed to “talk the language” of your production facility, regardless of size, product type or production configuration. Each NACEN GPSC installation is tailored to the needs and specifications of the facility.

- Flexibility – NACEN GPSC was designed to accommodate the unique production requirements of each sewn product facility. Installation of the system includes free adjustment of menus, result and printout configurations. There is no limit to the number or complexity of changes.

- Modem support – NACEN GPSC was one of the first companies in the industry to provide a ” help desk”, the modem support package, online help. These communication features permit modifications of the program, renewals and assistance by modem, internet, and telephone.

- Add-On Modules – optional modules which interact with the NACEN GPSC data base address cutting and spreading activities, capacity planning and ticket printing

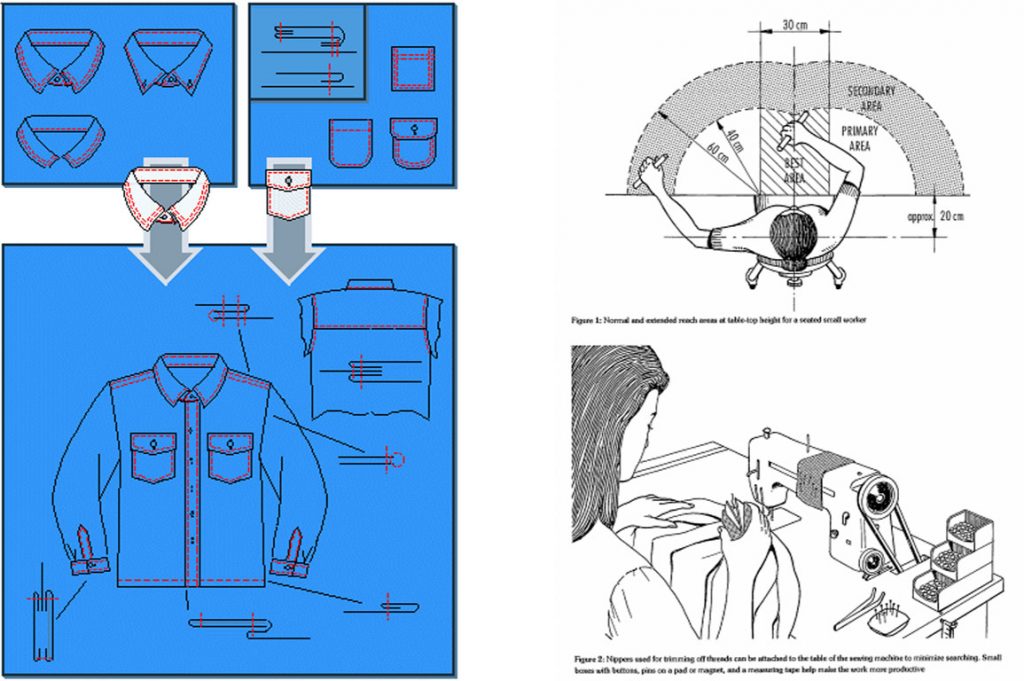

- Operator Training – It believes that the optimization of the operator is the key to superior productivity. The NACEN GPSC method specification is the first means of communication. The G.O.L.D.Bar System (General Operator Learning Data) option helps improve work efficiency by projecting training time for new, transferred or retrained workers. Adaptable to client data base.

- Production-responsive – The Quick Response “style” environment demands that sewn-products technology match the pace of today’s frantically changing production runs. It allows your facility company to anticipate, test and respond to hundreds of production variations – and to pre-engineer and pre-cost each variation with unequaled accuracy.

- Networking – The system allows sharing of information throughout a facility: Engineers, costing, management and the production-line can access for same information at the same time.

- Graphics, MPG and AVI compatible – It interfaces with Autocad (®) and Autosketch (®) as well as with any graphic Program that can produce “Bitmap” or WMF files, in order to produce work-place layouts, part enlargements, quality specifications and style profiles. In addition, NACEN GPSC can save MPG and AVI movies of operations for future reference.